Lean Six Sigma in healthcare is a transformative approach to enhancing patient care while optimising operational efficiency. By systematically identifying and eliminating waste and reducing process variability, Lean Six Sigma helps healthcare organisations deliver more consistently and efficiently high-quality care. This dual focus on quality and efficiency is critical for enhancing patient outcomes, reducing costs, and ensuring sustainable healthcare operations.

Understanding Lean Six Sigma

Lean Six Sigma combines two powerful methodologies: Lean, which focuses on removing waste and improving flow, and Six Sigma, which aims to reduce process variation and improve quality. Together, they provide a comprehensive framework for continuous improvement in healthcare settings. Lean tools, like value stream mapping and 5S, help streamline processes, while Six Sigma techniques, like DMAIC (Define, Measure, Analyse, Improve, Control), enhance process accuracy and reliability.

Enhancing Patient Care

The main goal of Lean Six Sigma in healthcare is to improve patient care. By reducing errors, decreasing wait times, and optimising resource utilisation, healthcare providers can offer better, faster, and more reliable services. In a hospital setting, Lean Six Sigma can streamline the patient admission process, reduce the incidence of medical errors, and ensure timely medication administration. These improvements lead to higher patient satisfaction and better health outcomes.

Improving Operational Efficiency

Operational efficiency is another critical benefit of Lean Six Sigma. Healthcare organisations often face challenges related to resource allocation, workflow inefficiencies, and high operational costs. Lean Six Sigma addresses these issues by identifying non-value-added activities and implementing process improvements. For example, hospitals can use Lean Six Sigma to optimise supply chain management, decrease inventory costs, and enhance the scheduling of surgeries and other procedures. These efficiencies translate into cost savings and more effective resource use.

Case Studies in Healthcare

Numerous healthcare organisations have successfully implemented Lean Six Sigma to achieve significant improvements. For instance, a hospital in the United States used Lean Six Sigma to reduce the turnaround time for lab results by 50%, leading to quicker diagnoses and treatments. Another example is a healthcare clinic that applied Lean Six Sigma principles to improve patient flow, resulting in a 30% reduction in patient wait times and a substantial increase in patient satisfaction scores.

Challenges and Considerations

While Lean Six Sigma offers substantial benefits, its implementation in healthcare also presents challenges. These include resistance to change, the need for staff training, and the complexity of healthcare processes. Successful adoption requires strong leadership, a commitment to continuous improvement, and effective communication across all levels of the organisation. Additionally, it is crucial to tailor Lean Six Sigma tools and techniques to fit the unique needs of the healthcare environment.

Conclusion

Lean Six Sigma is a dynamic procedure that enhances patient care and operational efficiency. By systematically identifying and eliminating waste and reducing variability, healthcare organisations can significantly improve quality and efficiency. These benefits lead to better patient outcomes, reduced costs, and more sustainable healthcare operations.

Our experienced professionals at Comprehensive Business Improvement Solutions (CBIS) can guide you in integrating Lean Six Sigma into your operations, helping you achieve excellence in patient care and operational efficiency.

Contact us today to learn more about our Lean Six Sigma training programs and start your journey towards operational excellence.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is DOE? In general usage, design of experiments (DOE) or experimental design is the...

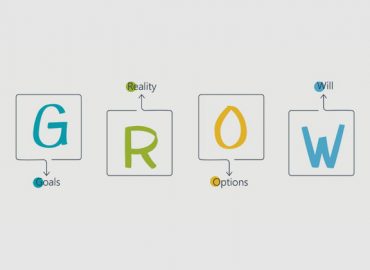

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Introduction In our lean six sigma projects, too often we spend all our time on...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

Overview Layout planning is one of the most important aspects of Lean manufacturing. In some...

As global competition continues to grow, the pressure to improve becomes more and more intense....

What is SMED? SMED is the term used to represent setup time and is often...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Introduction Value Stream Map (VSM) is a diagram of every step involved in the material...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.