What is DFSS?

Design for Six Sigma is used to perfect products and processes before use or release. When a new product design or new process design is needed and expected to perform at a six sigma level from the start or level considered to be “perfect” for the company or industry.

The intention of DFSS is to bring such new products and/or services to market with a process performance of around 4.5-sigma or better, for every customer requirement. This implies an ability to understand the customer needs and to design and implement the new offering with the reliability of delivery before launch rather than after!

What is DFSS methodology?

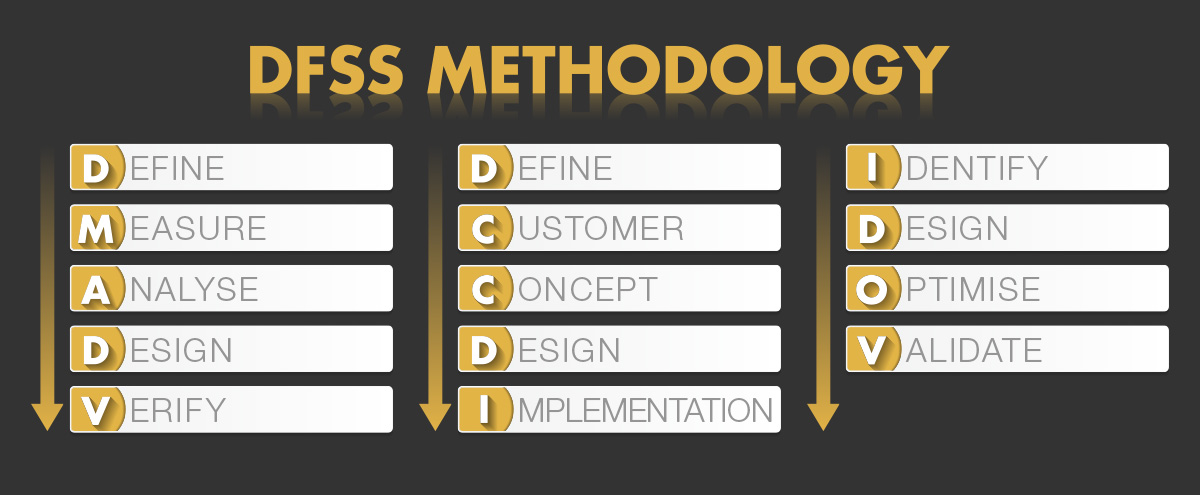

One popular Design for Six Sigma methodology is called DMADV. The five phases of DMADV are defined as:

- Define the project goals and customer requirements.

- Measure customer needs and specifications; benchmark competitors and industry.

- Analyse the product/process options to meet the customer needs.

- Design the product/process to meet the customer needs.

- Verify the design performance and ability to meet customer needs.

There are a few other known methodologies of DFSS such as DCCDI and IDOV. DCCDI is defined as Define, Customer Concept, Design and Implement. You can see that there are many similarities between these phases and the DMADV phases.

- Define the project goals.

- Customer analysis is completed.

- Concept ideas are developed, reviewed and selected.

- Design is performed to meet the customer and business specifications.

- Implementation is completed to develop and commercialise the product/service.

IDOV is a well-known design methodology, especially in the manufacturing world. The IDOV is defined as:

- Identify the customer and specifications

- Design translates the specification into functional requirements and solution alternatives.

- Optimise predicts and optimises the design and performance using advanced statistical tools

- Validate ensures the design will meet the specification.

The difference Between DMADV and DMAIC

The basic difference lies in the fact that DMAIC is a methodology that focuses on bringing about improvements to the existing products and services of the organisation, whereas DFSS aims at designing a new defect-free product or service to meet CTQ factors that will lead to customer satisfaction.

DMAIC focuses on detecting and solving problems with existing products and services, while the DFSS approach is that of preventing a problem.

Is DFSS only for manufacturing design?

Some people believe that DFSS is only applicable in manufacturing and for designing a new product, but it is not true. Design traditionally has been associated with products much more than for services, however, this is changing as companies realise that every product has associated services. A full approach to DFSS will consider every aspect from introducing a new product or service right through to ongoing commercialisation.

What are the main tools used in DFSS?

The main tools applied in a DFSS project through any of the DFSS methodologies may include:

- Market Analysis Tools,

- Project Management tools (Gantt Charts, PERT …)

- QFD – Quality Function Deployment,

- FMEA – Failure Mode Effect Analysis,

- DOE – Design Of Experiment, Taguchi Design

- Simulation techniques.

- Pugh Matrix,

- Prototyping,

- …

How CBIS can help you

Please contact us if you need more details on how our expert team can assists you in training and developing a new defect-free process/product/service using DFSS.

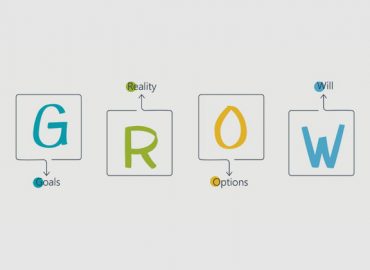

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

As global competition continues to grow, the pressure to improve becomes more and more intense....

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.