In today’s competitive business environment, small businesses face unique challenges in maximising efficiency and improving processes with limited resources. Lean Six Sigma, a methodology combining Lean manufacturing principles and Six Sigma tools, offers a structured approach to problem-solving and process improvement. By adopting Lean Six Sigma, small businesses can significantly improve quality, efficiency, and customer satisfaction, even with constrained resources.

Understanding Lean Six Sigma

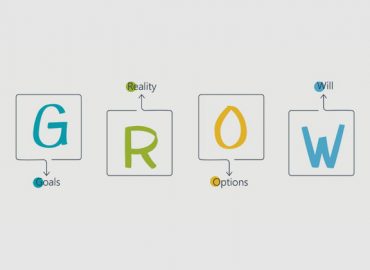

Lean Six Sigma integrates two methodologies: Lean focuses on eliminating waste and improving workflow, while Six Sigma emphasises reducing variation and enhancing quality. Together, they provide a comprehensive framework for improving processes and driving continuous improvement.

Core Principles of Lean Six Sigma

- Customer Focus: Understanding and fulfilling customer needs is of utmost importance. Lean Six Sigma prioritises delivering value to customers by aligning processes and outputs with their expectations.

- Data-Driven Decision Making: Decisions are based on data analysis rather than assumptions. This helps identify the fundamental causes of problems and measure the impact of improvements.

- Process Improvement: Continuous improvement is achieved by systematically identifying and eliminating waste, reducing variability, and optimising processes.

- Employee Involvement: Engaging employees at all levels fosters a culture of continuous improvement and leverages their insights for better problem-solving.

Steps to Implement Lean Six Sigma in Small Businesses

- Identify Key Processes and Problems: Identify critical processes directly impacting customer satisfaction and business performance. Use tools like SIPOC (Suppliers, Inputs, Processes, Outputs, Customers) diagrams to map processes and highlight areas for improvement.

- Collect and Analyse Data: Gather data on current performance to establish a baseline and identify areas of waste and variation. Statistical tools like Pareto charts, control charts, and root cause analysis can help understand the underlying issues.

- Set Clear Goals: For improvement, set SMART goals—specific, measurable, achievable, relevant, and time-bound. This approach helps maintain focus and track progress effectively.

- Form Cross-Functional Teams: Create teams comprising employees from different organisational functions and levels. Cross-functional teams bring diverse perspectives and enhance problem-solving capabilities.

- Train Employees in Lean Six Sigma: Provide training on Lean Six Sigma principles and tools. This empowers employees to contribute effectively to improvement projects and fosters a culture of constant improvement.

- Implement Improvement Projects: Execute improvement projects using Lean Six Sigma tools and techniques. Use the DMAIC (Define, Measure, Analyse, Improve, Control) framework to guide projects from problem identification to solution implementation and control.

- Monitor and Sustain Improvements: Establish control mechanisms to monitor the sustainability of improvements. Regularly review performance data, conduct audits, and make adjustments as necessary to maintain gains.

Benefits of Lean Six Sigma for Small Businesses

- Enhanced Efficiency: By streamlining processes and eliminating waste, small businesses can improve efficiency, reduce costs, and increase productivity.

- Improved Quality: Lean Six Sigma helps identify and eliminate defects, leading to higher-quality products and services.

- Better Customer Satisfaction: Meeting or exceeding customer expectations through improved processes enhances customer satisfaction and loyalty.

- Employee Engagement: Engaging employees in improvement initiatives enhances morale and creates a sense of ownership and accountability.

- Competitive Advantage: Improved efficiency, quality, and customer satisfaction provide a competitive edge in the marketplace.

Overcoming Challenges in Implementing Lean Six Sigma

- Resource Constraints: Small businesses often operate with limited resources. Prioritise improvement projects that offer the highest return on investment and effectively leverage existing resources.

- Change Management: Resistance to change can be a notable obstacle. To secure employees’ buy-in, clearly communicate the benefits of Lean Six Sigma and involve them in the change process.

- Sustaining Improvements: Maintaining gains can be challenging. Establish a culture of continual improvement and use control mechanisms to ensure improvements are sustained over time.

Conclusion

Lean Six Sigma offers a robust framework for small businesses to substantially improve efficiency, quality, and customer satisfaction, even with limited resources. Take the first step towards transforming your business today. CBIS specialises in helping small businesses implement Lean Six Sigma principles to achieve big results. Our team of experts provides tailored consulting, coaching, and training services designed to meet your business’s unique needs.

Ready to transform your business with Lean Six Sigma? Contact us today to learn more about our training programs and start your journey towards operational excellence.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is DOE? In general usage, design of experiments (DOE) or experimental design is the...

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Introduction In our lean six sigma projects, too often we spend all our time on...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

Overview Layout planning is one of the most important aspects of Lean manufacturing. In some...

As global competition continues to grow, the pressure to improve becomes more and more intense....

What is SMED? SMED is the term used to represent setup time and is often...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Introduction Value Stream Map (VSM) is a diagram of every step involved in the material...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.