As global competition continues to grow, the pressure to improve becomes more and more intense.

Executives and managers face many challenges:

- Increase sales

- Reduce cost

- Reduce inventory,

- Accurately forecast future demand

- Find the next market breakthrough

Although there are many ways to improve, many organizations have invested in at least one of the two most widespread methods of improvement Lean or Six Sigma.

There is an ongoing debate in the business world about whether Lean or Six Sigma is the better system to implement when it comes to streamlining business processes and eliminating waste. Both sides have proponents and detractors who can cite various situations in which one system may produce better results than the other.

Others argue that the best approach to creating the most efficient and effective business structure requires incorporating both Six Sigma and Lean principles. In order to view the debate in the proper context, however, you need to understand the differences and similarities between the two systems.

Six Sigma philosophy

Six Sigma is philosophy of process management developed by Motorola in the 1980s that uses statistical methods to minimize defects and waste.

Six sigma tools are used to improve the processes and products of a company. They are applicable across every discipline including: Production, Sales, Marketing, Design, Administration and Service.

Six sigma offers a wealth of tangible benefits. When skillfully applied by your people:

- Six Sigma reduces costs by 50% or more through a self-funded approach to improvement.

- Six Sigma reduces the waste chain.

- Six Sigma affords a better understanding of customer requirements.

- Six Sigma improves delivery and quality performance.

- Six Sigma provides critical process inputs needed to respond to changing customer requirements.

- Six Sigma develops robust products and processes.

- Six Sigma drives improvements rapidly with internal resources.

The Lean Approach

Lean manufacturing began in Japanese manufacturing in the late 1980s and early 1990s. It is most often associated with Toyota. Lean, as a management philosophy, is focused on improving process speed and quality through reduction of process wastes. The eight Lean process wastes all consume unnecessary energy, money, and time – those investments in process wastes are not things that provide value to the customer. By reducing activities that drive up cycle times or cost money unnecessarily, processes can become more efficient and more predictable.

A lean approach provides companies with tools to survive in a global market that demands higher quality, faster delivery and lower prices. Specifically,

- Lean manufacturing dramatically reduces the waste chain.

- Lean manufacturing reduces inventory and floor space requirements.

- Lean manufacturing creates more robust production systems.

- Lean manufacturing develops appropriate material delivery systems.

- Lean manufacturing improves layouts for increased flexibility.

Comparing Six Sigma and Lean

- First off, understand that there is a strong connection between Lean and Six Sigma. Both methodologies seek to make processes and the business as a whole more efficient by removing defects or waste through focused efforts that likely involve a project-based approach.

- Essentially, Six Sigma and Lean systems have the same goal. They both seek to eliminate waste and create the most efficient system possible, but they take different approaches toward how achieving this goal. In simplest terms, the main difference between Lean and Six Sigma is that they identify the root cause of waste differently

- Lean practitioners believe that waste comes from unnecessary steps in the production process that do not add value to the finished product, while Six Sigma proponents assert that waste results from variation within the process.

- One of differences can be found when Lean or Six Sigma is applied pervasively as a way of managing the business. Both include training as a core component but there is a subtle difference between the approaches used. While both Lean and Six Sigma need trained practitioners to be successful, Lean has an additional value placed on training that does not exist in Six Sigma. A core concept of a Lean culture is a cross-trained workforce. Cross-trained in the work process, not specifically in Lean tools. This is an important part of a Lean Transformation because a cross-trained workforce supports job rotation to keep workers from getting bored and complacent.

- Another significant difference is evident in the use of measurements. Both Lean and Six Sigma emphasize measuring performance, the approach is very different however. Six Sigma seeks to measure process performance relative to the problem being worked on at the project level or of the most important measures of business success through Dashboards.

- These dashboards\ cascade down from the top and rarely show up on the shop floor, so the workers don’t really know how they are doing. Lean, on the other hand, focuses measurements on the shop floor FIRST and places a high value on managers going to the Gemba, or shop floor to see for themselves how things are going. This suggests a bottom up approach to measurement, starting with the work cell and proceeding UP to the plant and the company from there. This is supported by Visual Factory concepts.

- Six Sigma is a tops-down management philosophy that only occasionally reaches the shop floor whose main practitioners are mid-level managers and engineers. Six Sigma projects are chosen by reviewing performance at a high level and imposing the change down with some involvement from the “doers”. Lean, on the other hand is characterized by the idea of “servant leadership” in which the leadership views one of its main functions to be enabling the success of the workers. Management goes to the floor to see what is happening, values effective communication, training, promotion, and learning and the initiative start and complete improvement work starts at the lowest level, the individual worker and the work cell member’s desire to improve their own work.

- Lean tends to be used for shorter, less complex problems-Often time driven- Focus is on eliminating wasteful steps and practices .Six Sigma is a bigger more analytical approach – often quality driven – it tends to have a statistical approach. Focus on optimizing the important steps – reducing defects.

- Although both methodologies are focused on process and quality improvement, Lean is formalization and codification of experience and judgment which is not a feature of Six Sigma. Lean emphasizes speed and waste, however Six Sigma emphasizes variation, defects and process evaluation.

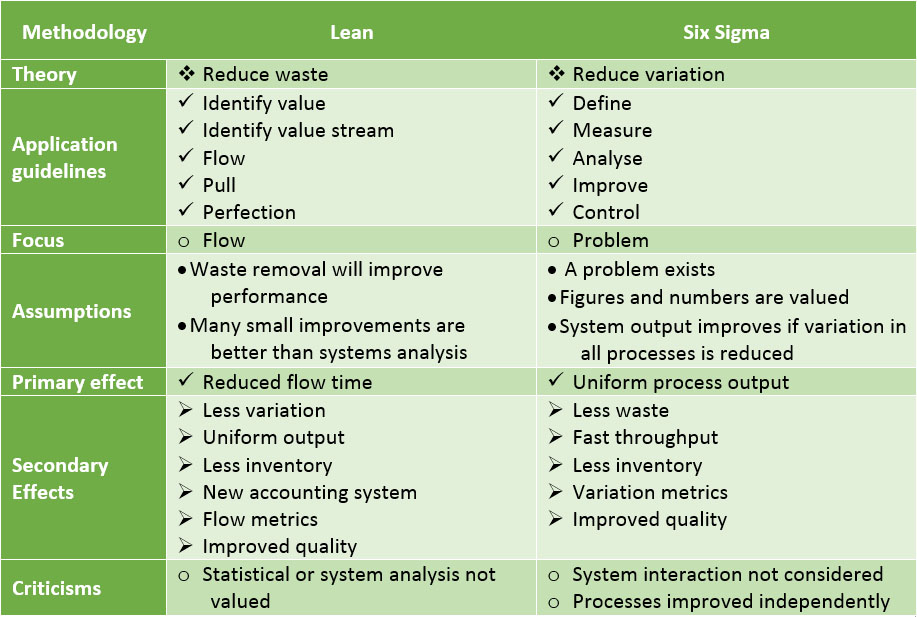

The principles of Lean and Six Sigma are compared. This table compares the principles of Lean with the principles of Six Sigma.

Lean Six Sigma

Lean Six Sigma is an approach to integrating the power of Six Sigma Tools and Lean Enterprise Tools which can be applied within an organization to create the fastest rate of improvement, maximize shareholder value, and increase customer delight

Lean Six Sigma (LSS) tries to combine the advantages of these two approaches and minimize the weakness of both. The Lean Six Sigma methodology entails using lean methodologies to identify and remove non-value adding activities and processes, and then applying Six Sigma methodologies to identify and eliminate process variation.

The fusion of Lean and Six Sigma is required because:

- Lean cannot bring process under statistical control, and

- Six Sigma alone cannot dramatically improve process speed or reduce invested capital.

By integrating tools and processes of Lean and Six Sigma, we’re creating a powerful engine for improving quality, efficiency, and speed in every aspect of business.

Embedding a rigorous methodology like lean six sigma into organizational culture is not a short journey, but it is a deep commitment not only to near-term results but also a long-term, continuous, even break-through results.

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.