In today’s highly competitive business environment, organisations continually seek ways to enhance efficiency, reduce waste, and improve overall performance. Lean Six Sigma, a methodology combining Lean manufacturing principles and Six Sigma, has become an essential strategy for achieving these goals. However, the benefits of Lean Six Sigma extend beyond organisational performance; they also offer employees significant personal and professional advantages. This guide explores the benefits employees can gain from Lean Six Sigma training, emphasising how it can contribute to career advancement and skill development.

Understanding Lean Six Sigma and Its Importance

Lean Six Sigma is an evidence-based approach to improving business processes by eliminating waste and reducing variability. By emphasising process improvement, organisations achieve greater efficiency, higher quality, and increased customer satisfaction. For employees, gaining proficiency in Lean Six Sigma principles enhances their ability to contribute to their organisation’s success and opens up new career growth opportunities.

Professional Benefits of Lean Six Sigma Training

- Career Advancement: Lean Six Sigma certification is highly regarded in many industries, making it a valuable credential for employees looking to advance their careers. By acquiring Lean Six Sigma skills, employees can leverage themselves as valuable assets to their organisation, often leading to promotions, salary increases, and leadership opportunities. The ability to lead process improvement initiatives and drive results is a sought-after skill set that distinguishes certified professionals from their peers.

- Enhanced Problem-Solving Skills: Lean Six Sigma training equips employees with advanced problem-solving tools and techniques. By learning how to analyse data, identify root causes of issues, and implement effective solutions, employees become more proficient in addressing challenges within their roles. This skill set applies to specific projects and enhances overall decision-making abilities, making employees more effective in their day-to-day responsibilities.

- Increased Efficiency and Productivity: One of the core principles of Lean Six Sigma is eliminating waste—whether it be time, resources, or effort. Employees trained in Lean Six Sigma recognise process inefficiencies and devise strategies to streamline operations. This focus on continuous improvement leads to increased productivity, enabling employees to complete tasks more efficiently and with higher-quality outcomes.

- Broadened Industry Knowledge: Lean Six Sigma training provides employees with a deep understanding of the best industry practices. By applying these practices within their roles, employees gain a broader perspective of how their work contributes to the organisation’s overall success. This expanded knowledge base enhances their current performance and equips them for future challenges and opportunities within their industry.

Personal Benefits of Lean Six Sigma Training

- Improved Leadership and Communication Skills: Lean Six Sigma training often involves working on cross-functional teams, requiring employees to collaborate with colleagues cross-functionally. This experience helps employees develop strong leadership and communication skills as they learn to manage projects, delegate tasks, and present their findings to stakeholders. These skills are invaluable not only in professional settings but also in personal development.

- Greater Job Satisfaction: Employees empowered to make meaningful contributions to their organisation’s success tend to experience higher levels of job satisfaction. Lean Six Sigma training gives employees the tools to effect positive change, creating a sense of accomplishment and fulfilment in their roles. As employees see the tangible results of their efforts, their engagement and motivation increase, contributing to a more positive work environment.

- Versatility and Adaptability: Lean Six Sigma principles apply across various industries and roles. By gaining expertise in this methodology, employees become more versatile and adaptable, using their skills in different contexts and settings. This adaptability is a crucial asset in today’s rapidly changing business landscape, where employees are often required to take on new challenges and responsibilities.

Lean Six Sigma training offers employees comprehensive skills beyond process improvement. Employees who invest in Lean Six Sigma training contribute to their organisation’s success and position themselves for long-term personal and professional growth.

Contact us today to learn more about our Lean Six Sigma training programs and to empower your team with Lean Six Sigma training. Our expert trainers are dedicated to helping your employees unlock their full potential and drive individual and organisational success.

What is DFSS? Design for Six Sigma is used to perfect products and processes before...

What is DOE? In general usage, design of experiments (DOE) or experimental design is the...

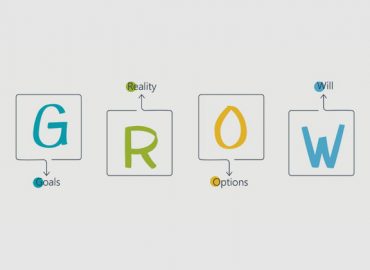

What is coaching? Coaching is a cyclical process of elevating the other persons’ awareness of...

Lean Six Sigma is a powerful method for improving existing products, processes and services. One...

Introduction In our lean six sigma projects, too often we spend all our time on...

What is a Kaizen Blitz? Kaizen definition has been Americanised to mean “Continual Improvement.” A...

Overview Layout planning is one of the most important aspects of Lean manufacturing. In some...

As global competition continues to grow, the pressure to improve becomes more and more intense....

What is SMED? SMED is the term used to represent setup time and is often...

Lean Six Sigma projects can lead to a rewarding experience and immense benefits for an...

Introduction Value Stream Map (VSM) is a diagram of every step involved in the material...

Attending our Public classroom physically or joining the team virtually from anywhere, according to the training calendar.

A flexible self-paced training for busy people along with our support by a dedicated coach, to solve the disadvantage of one-way online training

Delivering flexible and tailored training for your team and at your premises as a cost-effective solution for your team.